Latest

News, Opinions and What we’re up to.

Introducing Vogelensangh

We have been dropping hints over the past few weeks about our exciting new addition to the portfolio. Brick & Stone is thrilled to announce our new strategic partnership with Vogelensangh. With a shared commitment to excellence and customer satisfaction, this exclusive partnership promises to deliver exceptional value and choice to clients. Stay tuned for exciting developments from this incredible product range.

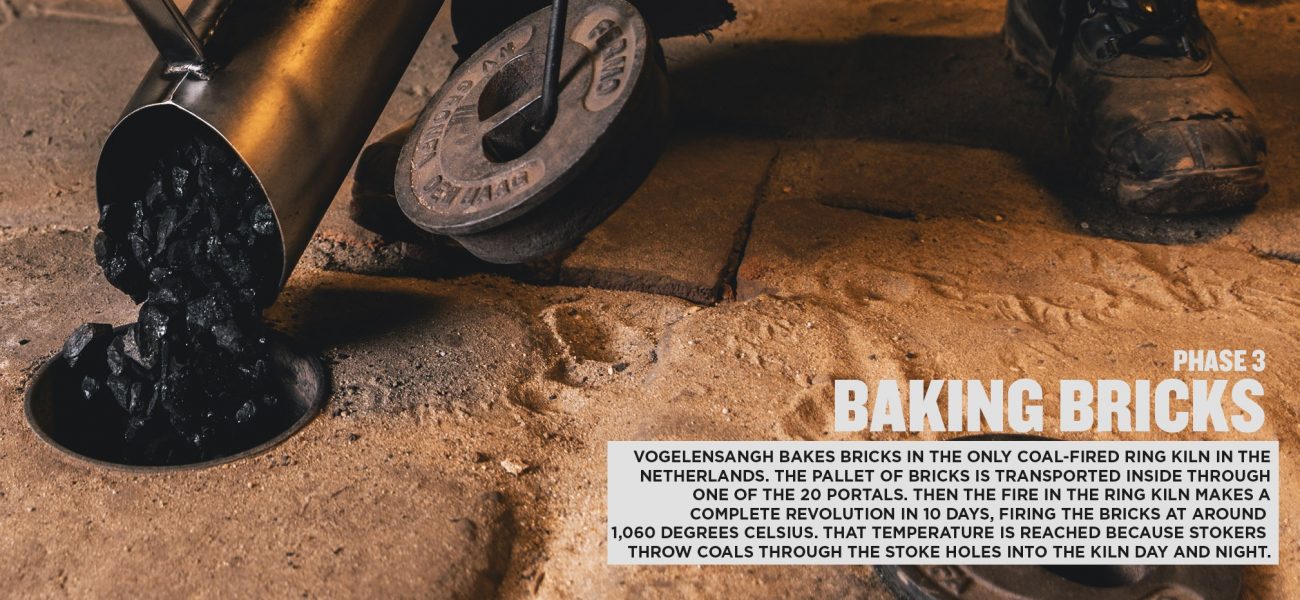

The factory then consisted of a compression building and a coal-powered ring kiln, which was top of its game at the time.

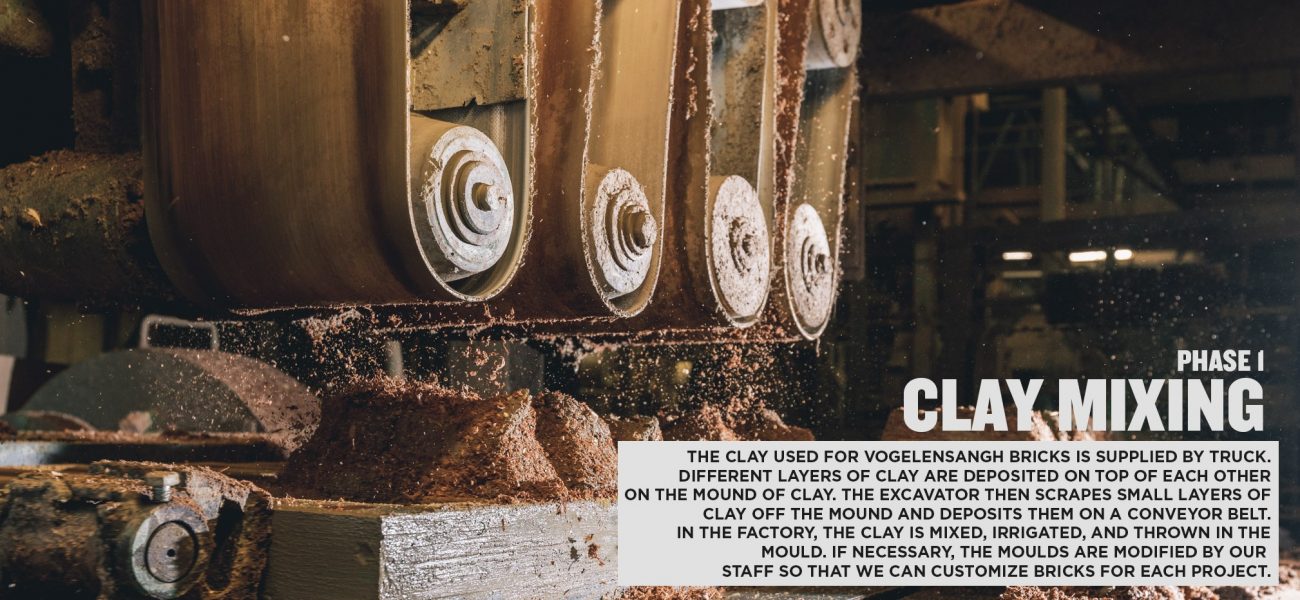

The clay for the bricks is dug up in the nearby fields and deposited on the mound of clay, where it is left to "rot" for a few months. It was then scraped from the mound and transported by wheelbarrow to the compression building to be mixed. The heavy mixing was carried out by a clay mill powered by a steam machine. The clay is then thrown into the moulds by hand.

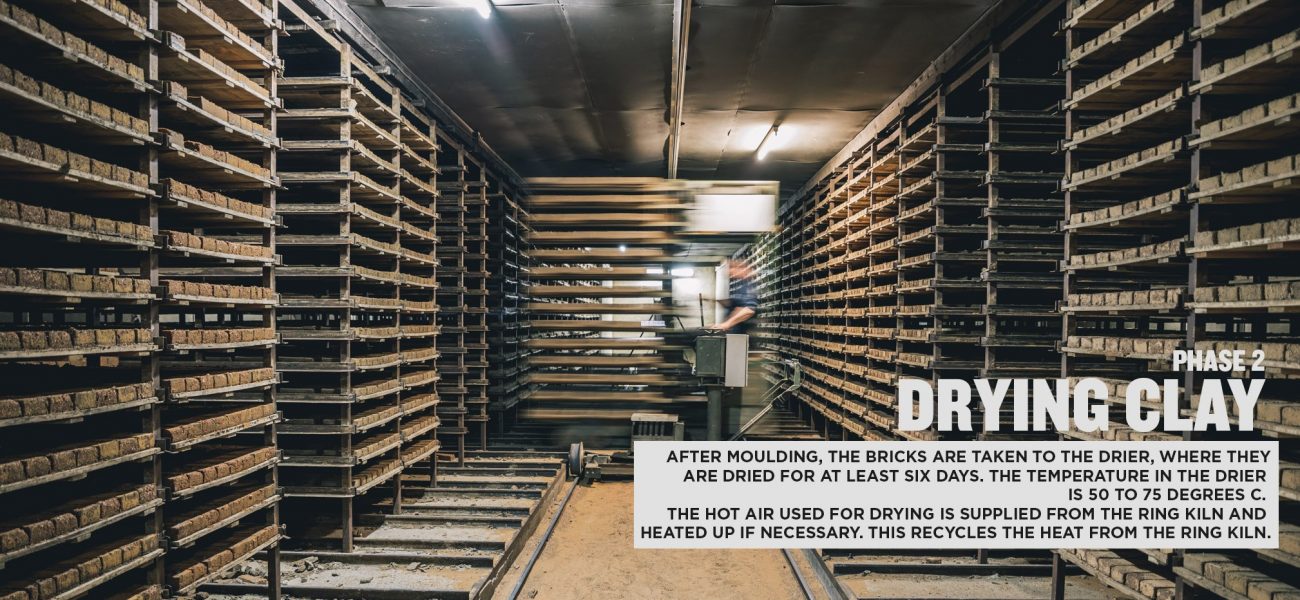

Once shaped, the bricks were transported by horse and cart to one of the many wooden huts on the site to allow the bricks to dry (this took weeks).

Once dry, the bricks were transported to the ring kiln and stacked in the coldest room. The gate door is bricked up, and the stokers (who tend the furnace) ensure the fire circulates from room to room in the ring kiln in 10 to 14 days.

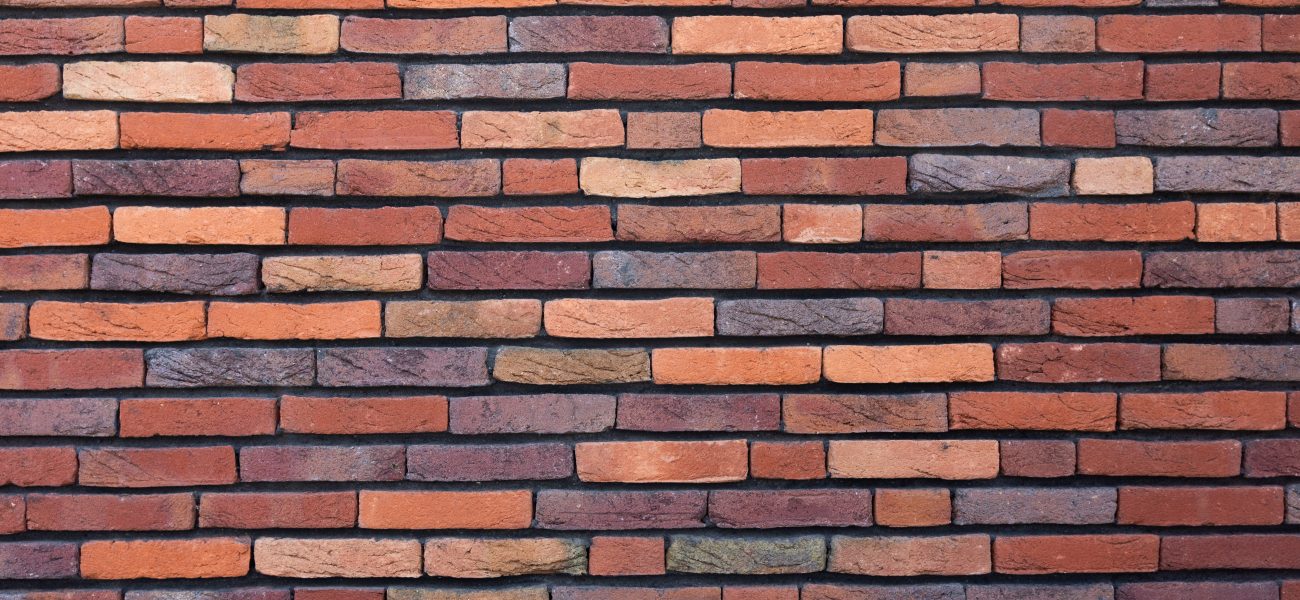

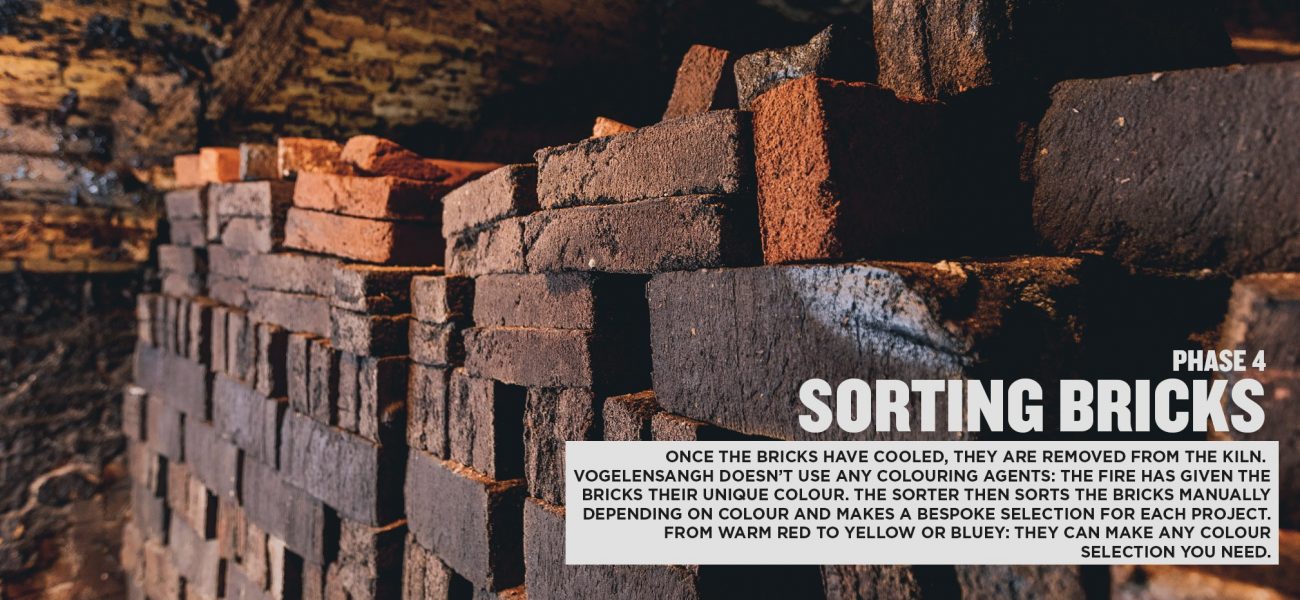

Once the bricks were cooled enough to be removed from the kiln, they were stacked on the field of bags and sorted by colour. The coals' heat and the ring kilns' flames give the bricks all kinds of shades of colour. Bricks closer to the fire are bluer, and bricks less close to the fire are redder.

Nowadays, the compressing and shaping machine now runs on electricity, and the wooden huts have been replaced with drying buildings where the bricks are dried on hot air from the ring kiln. But the ring kiln works just like it did 100 years ago.

At Vogelensangh, you buy bricks fired for 10 to 14 days on a coal-powered fire. The original colours of the bricks are caused by the coals and the flames: not by colouring agents. Additives aren't used, either. The bricks are high quality and sustainable to use.

To find out more drop an email to contact@brickandstone.eu or call us on 028 9083 0038.

Watch out for the Vogelensangh range coming to our website soon.